Lean process improvement is a system of steps that help organizations reduce waste by focusing on customer value. By identifying how customer value flows across every aspect of the organization, management & teams can then fine-tune and implement processes that create zero waste.

This training course will enable teams with the right tools to implement lean principles of process improvement into the very core of their culture, reducing waste and improving product and service value to the customer. Tools covered include 5S, 5W-2H, PDSA, DMAIC, Kaizen, Genchi Genbutsu.

Lean Training courses – Hong Kong's leading Lean Training course, delivered by LSS experts in Central and Hong Kong wide.

This Lean Process Improvement Training Course can be delivered at your premises by one of our expert local or international trainers or live online using our HIVE technology.

Contact us today for a quote.

If you’re not happy with the outcomes from

the course we offer a money back guarantee

For every participant

valued at $199 each

No one left behind

with our 1/2 price re-run promise

12-months access to the unique REACH Future Proofing Personal Development Dashboard with personally curated learning to develop agility to adapt to different people tasks and situations.

This two-day Lean Process Improvement training course will give your organization the foundational tools it requires to implement Lean.

Day one will explore the foundational Toyota precepts of Lean and the five improvement concepts - value, waste, variation, complexity, and continuous improvement.

The second day will focus on the actual tools for implementing these continual improvement concepts in their organization. Useful tools will include; Lean data mapping methods, 5S, 5W-2H, PDSA, DMAIC, Kaizen, Genchi Genbutsu.

This Lean process improvement training course will enable an entire organization to holistically apply lean thinking across every aspect of their value stream. From the worker to the CEO, the constant reevaluation of the value stream across each product and service family will challenge old thinking and create a new culture of lean thinking. Once the value of a product or service is identified, then unnecessary waste can be removed with continual process improvement.

Lean is not just limited to manufacturing and production, but also can equally be applied to service oriented industries like healthcare, government, education and agribusiness.

After completing this course, participants will have learned to:

Topic 1

Course Overview

Topic 2

Understanding Lean

Topic 3

The Toyota Production System

Topic 4

The Toyota Production System House

Topic 5

The Five Critical Improvement Concepts

Topic 6

Understanding Value with the Kano Model

Topic 7

Types of Waste

Topic 8

Creating a Lean Enterprise

Topic 9

The Plan, Do, Study, Act (PDSA) Cycle

Topic 10

Using the R-DMAIC-S Model

Topic 11

Lean Thinking Tools

Topic 12

Kaizen Events

Topic 13

Data Gathering and Mapping

Topic 14

A Plan to Take Home

Topic 15

Workshop Wrap-Up

If you’re not happy with the outcomes from

the course we offer a money back guarantee

For every participant

valued at $199 each

No one left behind

with our 1/2 price re-run promise

12-months access to the unique REACH Future Proofing Personal Development Dashboard with personally curated learning to develop agility to adapt to different people tasks and situations.

We take care of all of the details, so you don’t have to:

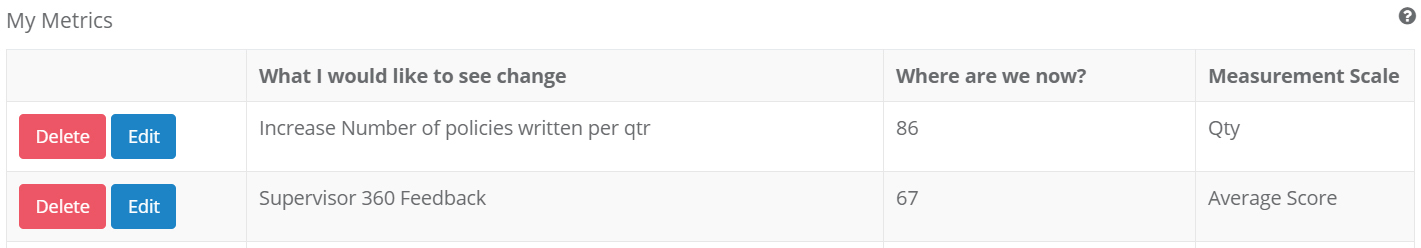

At the completion of training participants are encouraged to create an action plan, and invite an accountability buddy via their Orgmenta App.

In your Training Management Centre you have transparency to the action plans so you can see what people are going to do differently.

Our systems and people make it easy to identify how you’ll be able to measure impacts and then report on the success in the weeks or months after training.

It’s surprisingly easy to make it so that your system can automatically be up to date with all the training record details you need.

The most important foundation for communication and building meaningful relationships is listening, develop your skills with this micro eLearning course.

Not exactly what you needed? Try other courses in the Continuous Improvement Courses Category

Supporting leaders and teams around the globe, we're proud to mark 15 years of growth, innovation, and success. Thank you for being part of the PD Training journey. The future is looking bright!